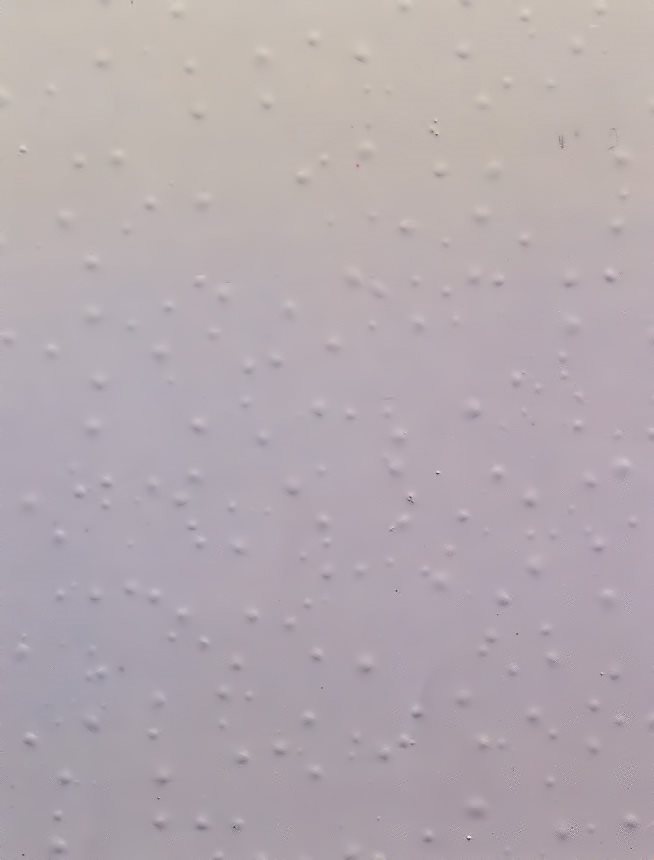

Blistering (Solvent)

TRB0004

Blistering can be caused by different actions so we have created two separate articles blistering (solvent) and blistering (humidity & other). This article covers Blistering (solvent). Blistering appears as ‘bubbles’ or pimples in the film of the coating.

Causes

- Solvent being trapped within primer or topcoat during the drying process

- Insufficient flash-off between coats. Where a second/third/fourth coat is put on before the coat underneath has had enough chance to dry. The solvents end up ‘trapped’ between the coats and blister out over time.

- Insufficient flash-off before force drying / stoving. This causes the solvent to literally boil and vaporise out of the film leaving hollow blisters in the paint film.

Prevention

- Do not under-thin materials, the product can be too ‘thick’ and can lead to solvents being trapped in the film.

- Allow primers and topcoats to flash-off (refer to technical data) before overcoating or force drying

- Do not use very fast thinners in warm conditions. This often leads to a heavy application technique, where the applicator is trying to keep a level of flow but fighting the fast drying solvent. Using a slow thinner is advised and will often cure a blistering issue.

Rectification

The blistering should be flatted down to a sound surface and re-painted. Any attempt to simply paint over solvent blistering can often result in more blistering at a later date.